Leo Shen, Senior Manager at R&D 1 Division of CoreTech SystemÂ

The Benefits of Electronic Potting

Using PU (polyurethane), silicone, or epoxy for electronic potting offers several advantages:

- Insulation Properties: PU, silicone, and epoxy provide effective insulation, safeguarding electronic components from moisture, dust, and other environmental factors, enhancing device stability and reliability.

- Component Protection: Components in electric vehicles and mobile products, especially high-power elements, are usually susceptible to mechanical vibrations or impact. These materials offer additional physical protection, reducing the risk of damage.

- High-Temperature Resistance: Potting materials typically exhibit excellent resistance to high temperatures, helping to address the heat generated during prolonged operation of high-power chargers.

- Filling and Sealing: PU, silicone, and epoxy can fill and seal gaps around electronic components, minimizing the possibility of moisture and dust ingress, and improving product lifespan.

Electronic potting significantly improves electronic parts and product reliability, durability, and safety.

Challenges in the Potting ProcessÂ

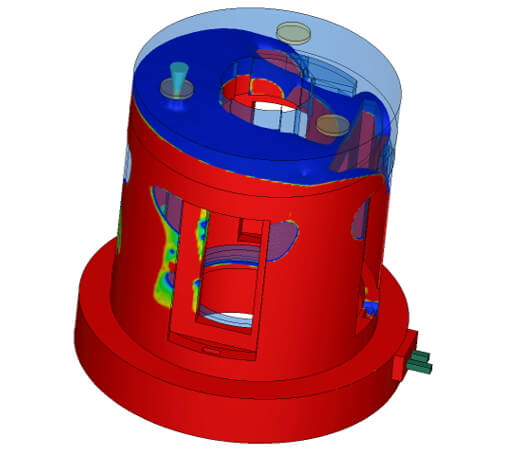

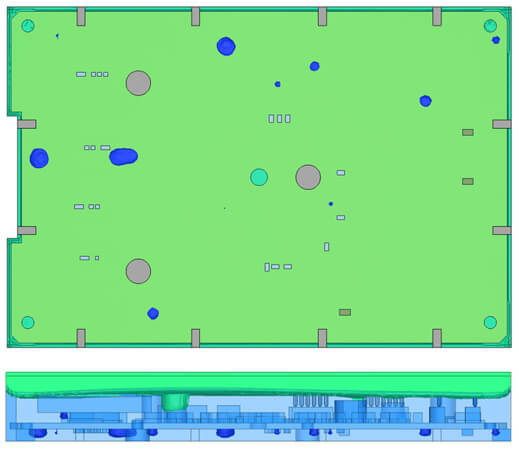

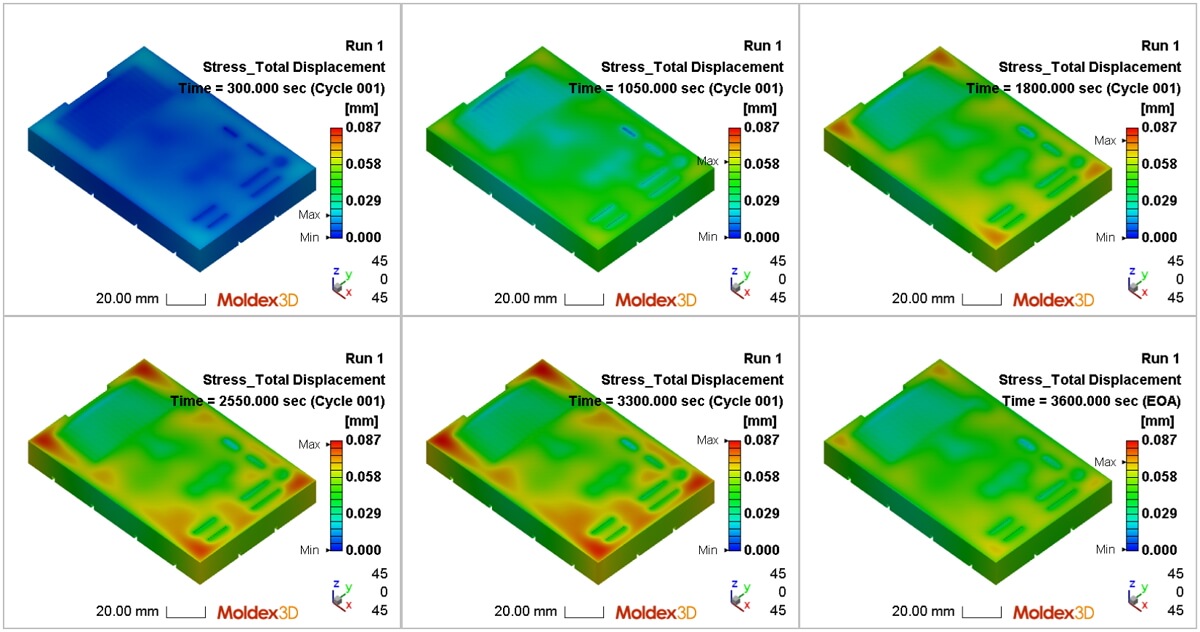

Challenges such as air trapping (Figures 1 and 2), the thermal effects of phase transition, and residual stress (Figure 3) accumulated from chemical shrinkage must be addressed during the potting process. These factors can impact product lifespan and reliability estimation.

Figure 1. Air traps in electric motor

Figure 2. Air traps under PCB

Figure 3. Residual stress

Moldex3D Electronic Potting Can Help

Moldex3D Electronic Potting simulation makes it possible to model the fluid dynamics during the potting process, effectively predicting the location and size of air traps. Furthermore, the simulation comprehensively analyzes temperature changes, chemical reactions, curing degree, and shrinkage during the phase transition process.

Confirm and Improve Processing Condition Settings

- Flow, temperature, phase, and conversion field simulation.

- Introduce the effects of surface tension, capillary force, and gravity.

- Optimize the dispenser and path design.

- Detect potential defects and issues, such as air traps

Post Mold Cure Warpage Simulation

- Observe the phase transition process through numerical simulation.

- Thoroughly consider the stress relaxation and chemical shrinkage.

- Predict deformation in the post-mold cure process via temperature, conversion, and stress distribution simulation.

Enhancing Industrial Precision through Moldex3D Numerical Simulations

Numerical simulations provide comprehensive information at each time point of the process, from the motion state of the flow process to phase-transition and temperature-induced shrinkage and deformation. These rich details can help the industry evaluate product yield, precisely control product quality, and significantly accelerate product evolution.

Door And Window Sealing Strip Series

Door And Window Sealing Strip Series,Door Window Frame Seal Strip,Door Seal Strip,Wind Proof Rubber Strip

HEBEI JIEXING RUBBER SEALS CO.,LTD , https://www.jiexingrubber.com